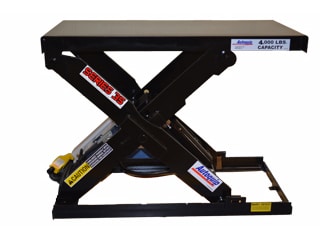

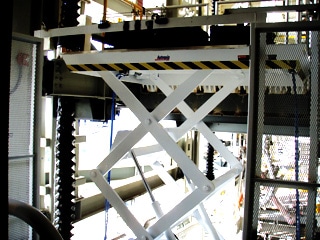

Autoquip Series 35 Scissor Lift Tables are ready to help you reach new levels of performance and productivity. Each Series 35 model is designed and built to provide long-service life, durability, and outstanding lifting power.

We offer a large selection of models suited to fit most applications such as pallet handling, parts assembly, and ergonomic work positioning. Special applications where one of our standard models is not suitable, the Series 35 product line is easily modified to deliver a lift table right for you.

Series 35 models range in travel from 24″ to 60″ with lifting capacities up to 15,000 lbs. We offer many options and accessories to expand the versatility of your lift table – controls, portability set, accordion skirting, turntables, and more.

Our Series 35 Scissor Lift Tables offer an unsurpassed value providing years of dependable service. Visit our models page to find the right Series 35 lift table for your project. If you don’t find it there, contact our sales department for a full range of lift products designed to help you improve productivity.